Get PLC Programming Support

The configurable, rugged nature of PLCs (Programmable Logic Controllers) puts them at the center of every industrial automation initiative. When set up correctly, they can improve productivity, flexibility, and be relatively easy to maintain. But when they’re not, you can have a machine that doesn’t run at its full potential, or even worse, seems to always be down, costing you time and money.

When you need support designing, programming, or troubleshooting your system, you want to go with the experts. That’s where we come in. We are a small, highly-skilled team of industrial automation engineers. We work with many PLC platforms and the technologies that they integrate with. Some of our core services are:

Siemens, Allen-Bradley (Rockwell), and Beckhoff PLC programming

HMI and SCADA Programming

MES Integration

Motion Control and Robotics Programming

Barcode Scanners and RFID Tracking

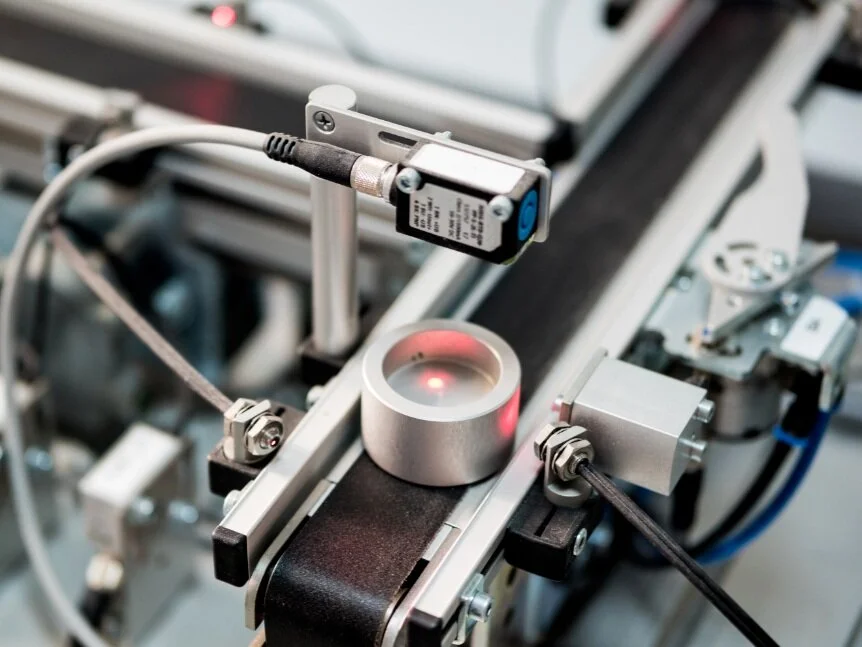

Cameras and Vision Systems

Pneumatic and Hydraulic Actuators

Safety Controllers, Scanners, Sensors, and Interlocks

Data Handling and SQL Databases

WHAT OUR CUSTOMER SAY

We know industrial automation inside and out.

Faster Startups

Our engineers’ extensive expertise and design process comes in handy when it comes time for commissioning. When brought in early, we can program the system offline and simulate the code ahead of time. We use a modular programming style that makes it fast and easy to update during commissioning. And our experience gives us the ability to spot and troubleshoot issues that come up.

Moving Toward Industry 4.0

Industry 4.0 integration is all about collecting data and interacting with it in a useful way. We can figure out where the data should come from and where it should go, like to AWS, an on-premise historian, or something custom. Once we have the data, we can implement the way that people across your organization can access it and use it to improve your business.